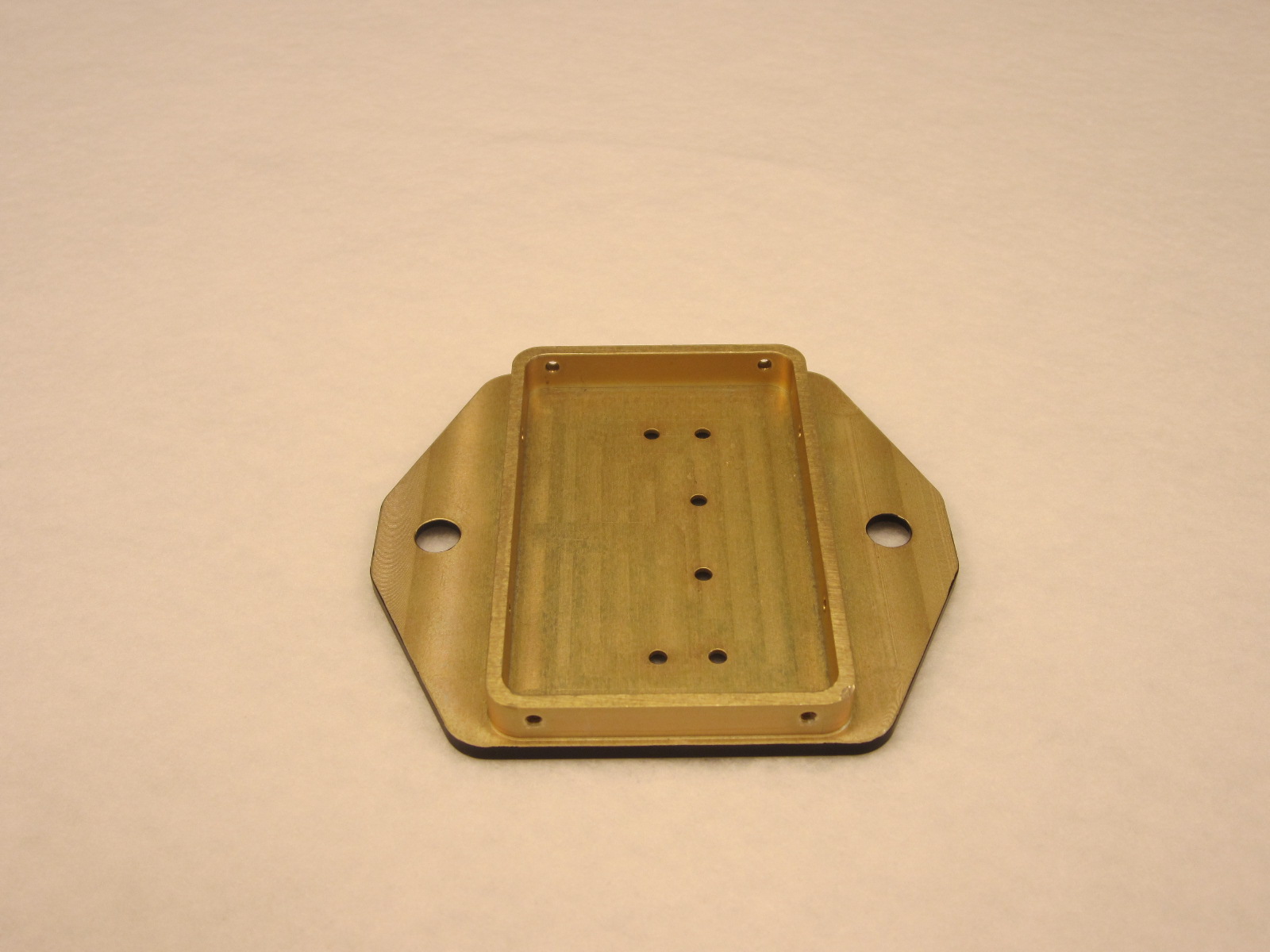

Chemical Film Process . Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. The chem film process is fairly simple, and though it may vary between different suppliers. This classification requires aluminum parts to remain in the chemical film solution for a specific. It acts as a barrier against. However, the conversion coating process will follow a certain pattern: It’s primarily used to passivate aluminum as it protects this.

from www.coastlinemetalfinishing.com

Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. It’s primarily used to passivate aluminum as it protects this. The chem film process is fairly simple, and though it may vary between different suppliers. However, the conversion coating process will follow a certain pattern: It acts as a barrier against. This classification requires aluminum parts to remain in the chemical film solution for a specific. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface.

Chemical Film Metal Surface Coatings Coastline Metal Finishing

Chemical Film Process The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. It’s primarily used to passivate aluminum as it protects this. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. It acts as a barrier against. This classification requires aluminum parts to remain in the chemical film solution for a specific. However, the conversion coating process will follow a certain pattern: The chem film process is fairly simple, and though it may vary between different suppliers.

From www.film-photography-blog.com

Film processing chemistry, how does it work? Film Photography Blog Chemical Film Process The chem film process is fairly simple, and though it may vary between different suppliers. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. This classification requires aluminum parts to remain in the. Chemical Film Process.

From pubs.rsc.org

Expanding plastics recycling technologies chemical aspects, technology Chemical Film Process The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. It’s primarily used to passivate aluminum as it protects this. However, the conversion coating process will follow a certain pattern: Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. It acts as a. Chemical Film Process.

From www.degruyter.com

Facile growth of aluminum oxide thin film by chemical liquid deposition Chemical Film Process Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. The chem. Chemical Film Process.

From www.tekra.com

Tek Tip Amorphous vs. SemiCrystalline Polyester Tekra, LLC Chemical Film Process It’s primarily used to passivate aluminum as it protects this. It acts as a barrier against. This classification requires aluminum parts to remain in the chemical film solution for a specific. The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. Chem film or alodine is a chemical conversion coating that’s mostly used. Chemical Film Process.

From www.intechopen.com

Introductory Chapter The Prominence of Thin Film Science in Chemical Film Process Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. The chem film process is fairly simple, and though it may vary between different suppliers. This classification requires aluminum parts to remain in the. Chemical Film Process.

From www.film-photography-blog.com

Film processing chemistry, how does it work? Film Photography Blog Chemical Film Process This classification requires aluminum parts to remain in the chemical film solution for a specific. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. However, the conversion coating process will follow a certain pattern: Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from. Chemical Film Process.

From pubs.rsc.org

Expanding plastics recycling technologies chemical aspects, technology Chemical Film Process Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. It acts as a barrier against. The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection. Chemical Film Process.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Chemical Film Process It’s primarily used to passivate aluminum as it protects this. The chem film process is fairly simple, and though it may vary between different suppliers. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. Alodine finishing, also called chem film, is a chromate conversion coating that offers. Chemical Film Process.

From www.youtube.com

Mix Developer G128 Chemical Film Radiography Testing YouTube Chemical Film Process Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. The chem film process is fairly simple, and though it may vary between different suppliers. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. It’s primarily used to passivate aluminum as it protects. Chemical Film Process.

From ehive.com

Equipment Film and Chemical Processing Charts; Ca 1970s; AR12468 eHive Chemical Film Process The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. This classification requires aluminum parts to remain in the chemical film solution for a specific. Chem film or alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. Chemical films will vary widely when it comes to composition and. Chemical Film Process.

From www.scientific.net

Research of Chemical Film Process on Metal Surface Chemical Film Process This classification requires aluminum parts to remain in the chemical film solution for a specific. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. It’s primarily used to passivate aluminum as it protects this. The chem film process creates a thin, protective outer layer that tightly adheres. Chemical Film Process.

From www.artnews.com

Best Photography Chemicals for Developing Film Chemical Film Process The chem film process is fairly simple, and though it may vary between different suppliers. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. It’s primarily used to passivate aluminum as it protects this. Chem film or alodine is a chemical conversion coating that’s mostly used to. Chemical Film Process.

From www.researchgate.net

Chemical vapor deposition (CVD) method (a) Schematic illustration of Chemical Film Process This classification requires aluminum parts to remain in the chemical film solution for a specific. It’s primarily used to passivate aluminum as it protects this. The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts,. Chemical Film Process.

From boppfilms.blogspot.com

BOPP Film Production Process.... MasterBatches Chemical Film Process It acts as a barrier against. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. However, the conversion coating process will follow a certain pattern: Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. The chem film. Chemical Film Process.

From www.youtube.com

xray film processing chemical l developer & fixer solution l Chemical Film Process It acts as a barrier against. The chem film process is fairly simple, and though it may vary between different suppliers. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. It’s primarily used to passivate aluminum as it protects this. Alodine finishing, also called chem film, is. Chemical Film Process.

From www.researchgate.net

A schematic view of sol‐gel process for the ZnO thin film processing Chemical Film Process The chem film process is fairly simple, and though it may vary between different suppliers. It acts as a barrier against. However, the conversion coating process will follow a certain pattern: The chem film process creates a thin, protective outer layer that tightly adheres to the metal surface. Alodine finishing, also called chem film, is a chromate conversion coating that. Chemical Film Process.

From www.mdpi.com

Coatings Free FullText A Review on Sustainable Manufacturing of Chemical Film Process Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. It’s primarily used to passivate aluminum as it protects this. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. The chem film process is fairly simple, and though. Chemical Film Process.

From www.coastlinemetalfinishing.com

Chemical Film Metal Surface Coatings Coastline Metal Finishing Chemical Film Process This classification requires aluminum parts to remain in the chemical film solution for a specific. Chemical films will vary widely when it comes to composition and type, so the processes will vary based on the chemical film. Alodine finishing, also called chem film, is a chromate conversion coating that offers corrosion protection in metal parts, especially. However, the conversion coating. Chemical Film Process.